Batteries have been part of our lives since the days of handheld radios and clunky portable flashlights leading us through the dark. Fast-forward to present day and the world is now at our fingertips with immediate access by way of our cell phones and laptops; battery powered marvels that have changed the fabric of our lives. Even our love affair with big engines and four-barrel carburetors or twin turbos are not immune to the gratification of instant torque provided by dual electric motors.

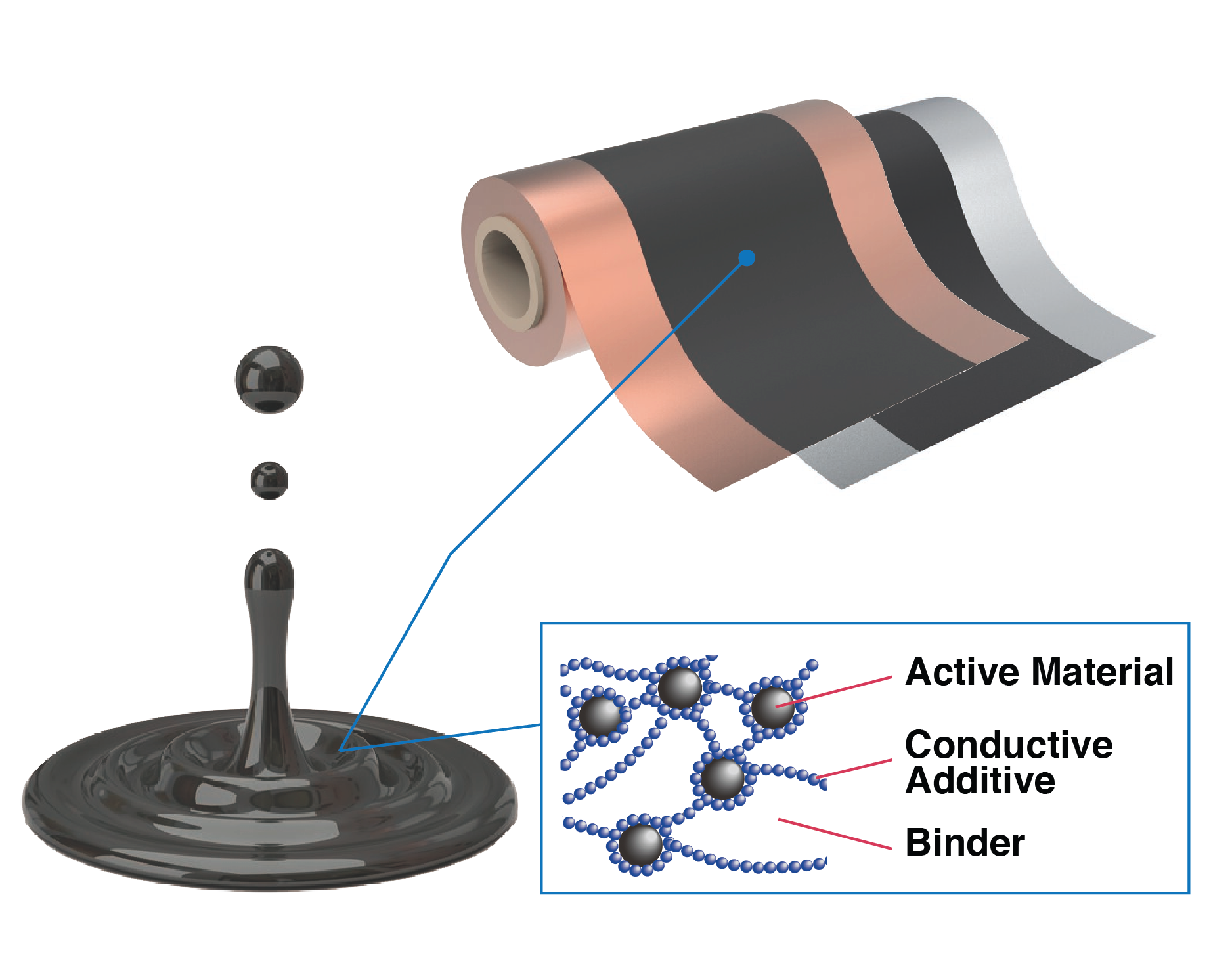

There is a need now to push the boundaries of battery capacity and efficiency even further as we are all acutely aware of fossil fuel driven climate change. Viscosity is a parameter that is closely tied to battery performance and manufacturability. Slurries are a mixture of cathode/anode materials, polymer binders, additives, all in a solvent medium. These slurries are a "very complex suspension system", with rheological propertied of the slurries affecting important attributes that impact finished electrodes. (rheonics)

Without an accurate and precise viscosity measuring instrument there is no way to understand how these components interact. For instance, is the formulation non-Newtonian? And, if it so, is it shear thinning and to what degree? How much does solvent evaporation change viscosity? These are all questions that must be answered for proper slurry manufacturing and stability.

LEARN MORE ABOUT BATTERY VISCOSITY

With this push in battery research, the best and brightest work to bring about possibilities we can only dream of. And, with any great endeavor the right tools must be used for without the right tool’s success is inherently limited. RheoSense viscometers are the most accurate and precise in the industry and have the widest dynamic range to fully characterize a sample. With RheoSense VROC® technology shear rate sweeps are easily done to understand non-Newtonian behavior to mimic different manufacturing processes. Slot dye, doctor blade each have a distinct associated shear rate range that is easily replicated. Furthermore, RheoSense viscometers are a closed system so evaporation is not an issue. Because slurries are designed to dry to a solid, viscometers open to the atmosphere are not well suited for testing volatile samples; gap edge will solidify as the bulk stays fluid leading to poor repeatability.

Without the right tools progress is slowed and breakthroughs could be jeopardized. RheoSense VROC technology allows the researcher to do what cannot be done with traditional viscometers. Why limit yourself when the right tool is available? Contact us to learn more about how our VROC viscometer closed systems and small sample size requirements make our technology the ideal solution for viscosity measurements of slurries.

Written by: Rick Paulino, RheoSense Regional Sales Manager